Hot Products

Our PVC tarpaulin base fabric includes four categories: high-strength polyester fabric, high-strength industrial silk fabric, fiberglass fabric, organic silicon fabric, etc., which facilitate customers' one-stop procurement.

ABOUT US

Professional Supplier Of Tarpaulin

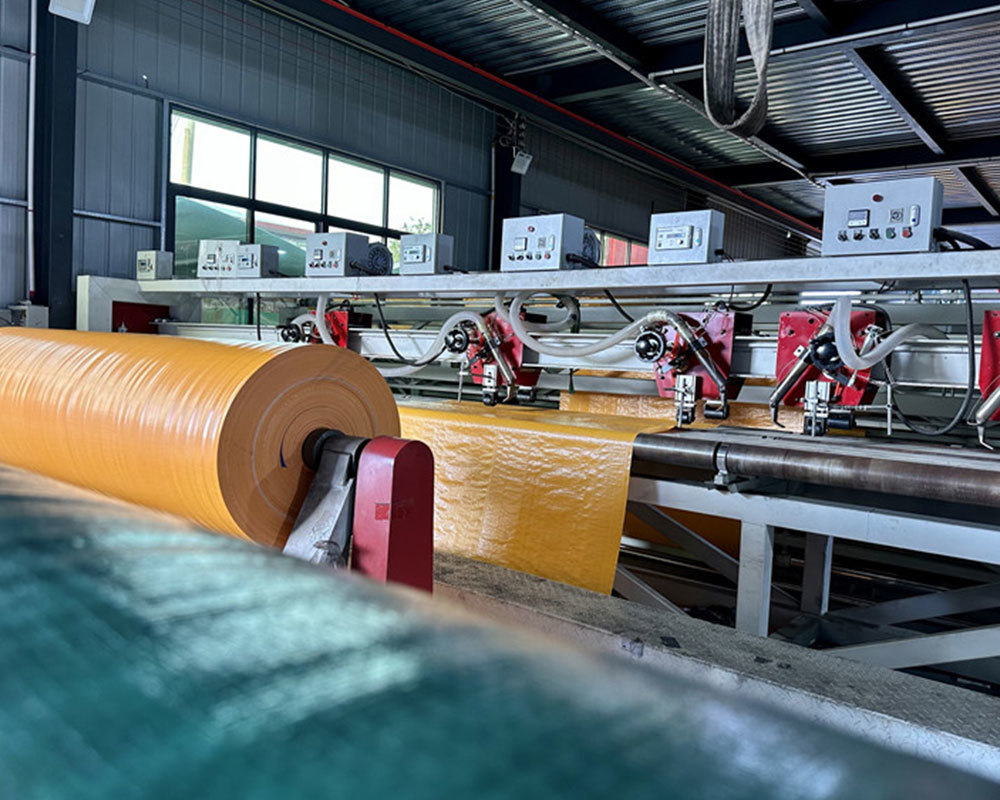

Founded in 2002, it has a 20-year development history in the industry. For many years, our company has always adhered to independent research and development, supported sample processing, and strictly controlled the quality of raw materials, with very comprehensive technical experience. Our company's products cover four major categories: traditional adhesive tape, silicone single-sided coating fabric, knife scraping fabric, and fiberglass fireproof fabric. Based on this, we have customized more than 200 different products according to the needs of different customers, forming our characteristic of supporting small order customization. Our customers are spread all over the country and have formed a good reputation.

Technical experience

Customized product quantity

Company establishment

OEM CUSTOMIZED SERV

We firmly believe that products are the responsibility of the country and families, and quality is the guarantee for the survival of enterprises. We actively and seriously engage in domestic and international trade, with customers spread across the country and forming a good reputation.

Customized

Application Display

The parameters such as yarn count and density directly affect the physical and mechanical properties as well as the cost of tarpaulin. Tarpaulin products have a wide range of applications in various fields due to their diversity and practicality.

★ Comprehensive production scope: There are four major categories: high-strength polyester fabric, high-strength industrial silk fabric, fiberglass fabric, and silicone fabric.

★ Our PVC tarpaulin is customized according to customer needs, coated with polyvinyl chloride (PVC) paste resin and added with various chemical additives such as flame retardants, mold inhibitors, anti-aging agents, anti-static agents, etc., to achieve different waterproof, mold proof, cold resistant, anti-aging, anti-static and other properties:

★ Our company can flexibly customize products with different thicknesses, weights, breaking strength, tear elongation, and tear strength according to customer requirements.

Technology

Over 20 years of development history. Adhere to independent research and development, support sample processing, strictly control the quality of raw materials, and have very comprehensive technical experience.

Strong production team, after-sales service intimate

Flame Retardant Effect Test Video

Our company's products cover four major categories: traditional adhesive tape, silicone single-sided coating fabric, knife scraping fabric, and fiberglass fireproof fabric. Based on this, we have customized more than 200 different products according to the needs of different customers, forming our characteristic of supporting small order customization. Our customers are spread all over the country and have formed a good reputation.

Blogs & Articles

Our products are entering the international market, and we believe that with our excellent product quality and good after-sales service system, we will be able to occupy a place in the international market.

2024-11-25

Guide you to learn about waterproof canvas

From fabrics made from natural fibers to synthetic fibers and waterproof treatment technologies, waterproof canvas has become an indispensable material in people's daily lives.

2025-10-02

Unlocking the Potential of 2×2 High Strength Silk Blue in Textiles

In the textile industry, 2×2 High Strength Silk Blue represents a compelling option for manufacturers and designers looking to innovate and elevate their products. This fabric, characterized by its distinctive weave pattern and high tensile strength, offers numerous advantages in both durability and aesthetic appeal. The term "2×2" refers to the weaving method, indicating that two yarns are woven

2025-09-28

One side coated green cambric suppliers

Tangchi is among trusted One side coated green cambric suppliers, offering durable fabrics for global markets with quality-focused solutions