Understanding One Side Coated Green Cambric: Features and Applications

Apr 13,2025

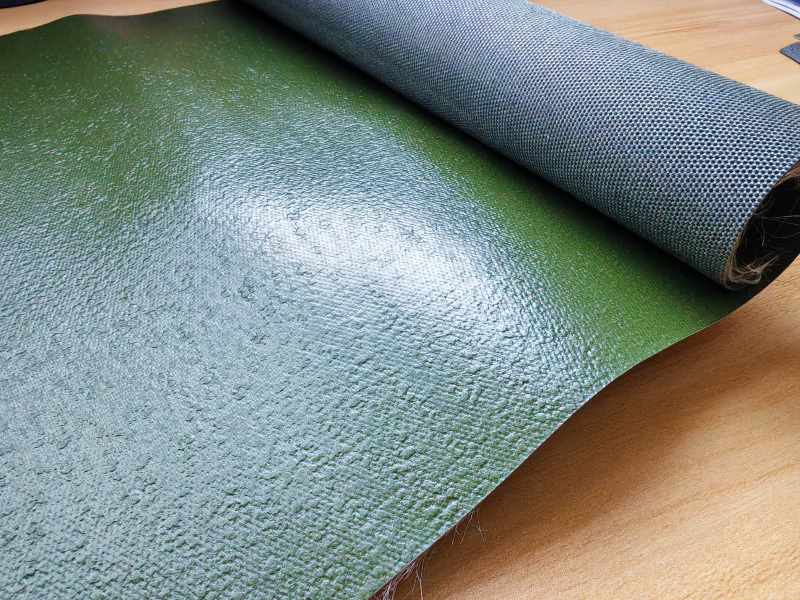

One side coated green cambric is a versatile textile that has garnered attention in various applications due to its unique properties. This type of cambric features a coated finish on one side, enhancing its durability and functional attributes, making it an excellent choice for multiple industries, particularly in the realm of chemical fibers.

One of the most significant advantages of one side c

One side coated green cambric is a versatile textile that has garnered attention in various applications due to its unique properties. This type of cambric features a coated finish on one side, enhancing its durability and functional attributes, making it an excellent choice for multiple industries, particularly in the realm of chemical fibers.

One of the most significant advantages of one side coated green cambric is its resistance to wear and tear. The coating provides an additional layer of protection that can help the fabric withstand harsh conditions, thereby extending its longevity. This durability makes it an ideal material for use in products that require frequent handling or exposure to environmental factors.

The green color of the cambric not only offers aesthetic appeal but also highlights its potential for eco-friendly applications. Many manufacturers are increasingly focused on sustainability, and using green cambric can be part of a broader initiative to utilize materials that are less harmful to the environment. This aligns well with current market trends where consumers are becoming more conscientious about the materials used in the products they purchase.

In terms of versatility, one side coated green cambric can be used in various applications ranging from apparel to protective gear, home textiles, and even industrial uses. It can be utilized for making bags, covers, and other items that demand a combination of strength and flexibility. Given its coated surface, it often exhibits water-resistant properties, making it suitable for outdoor gear that requires protection from moisture.

From a manufacturing perspective, the processing of one side coated green cambric involves specific techniques to ensure that the coating adheres correctly and maintains its integrity through the lifecycle of the fabric. Companies working with this material should focus on the quality of the coating and the base fabric to ensure optimal performance.

Lastly, while one side coated green cambric presents numerous benefits, it is crucial for professionals in the textile industry to understand its limitations as well. Certain chemicals or prolonged exposure to intense sunlight may affect the integrity of the coating, which could impact the fabric’s performance over time. Therefore, thorough testing and quality control are paramount when integrating this material into any production line.

In conclusion, one side coated green cambric stands out as a practical and versatile fabric choice in the textile industry. Its unique characteristics and wide range of applications make it valuable for manufacturers and consumers alike. By understanding its properties and potential uses, professionals can make informed decisions that align with current trends and demands in the market.

One of the most significant advantages of one side coated green cambric is its resistance to wear and tear. The coating provides an additional layer of protection that can help the fabric withstand harsh conditions, thereby extending its longevity. This durability makes it an ideal material for use in products that require frequent handling or exposure to environmental factors.

The green color of the cambric not only offers aesthetic appeal but also highlights its potential for eco-friendly applications. Many manufacturers are increasingly focused on sustainability, and using green cambric can be part of a broader initiative to utilize materials that are less harmful to the environment. This aligns well with current market trends where consumers are becoming more conscientious about the materials used in the products they purchase.

In terms of versatility, one side coated green cambric can be used in various applications ranging from apparel to protective gear, home textiles, and even industrial uses. It can be utilized for making bags, covers, and other items that demand a combination of strength and flexibility. Given its coated surface, it often exhibits water-resistant properties, making it suitable for outdoor gear that requires protection from moisture.

From a manufacturing perspective, the processing of one side coated green cambric involves specific techniques to ensure that the coating adheres correctly and maintains its integrity through the lifecycle of the fabric. Companies working with this material should focus on the quality of the coating and the base fabric to ensure optimal performance.

Lastly, while one side coated green cambric presents numerous benefits, it is crucial for professionals in the textile industry to understand its limitations as well. Certain chemicals or prolonged exposure to intense sunlight may affect the integrity of the coating, which could impact the fabric’s performance over time. Therefore, thorough testing and quality control are paramount when integrating this material into any production line.

In conclusion, one side coated green cambric stands out as a practical and versatile fabric choice in the textile industry. Its unique characteristics and wide range of applications make it valuable for manufacturers and consumers alike. By understanding its properties and potential uses, professionals can make informed decisions that align with current trends and demands in the market.

Hot Tags:

Related Posts

Contact Us

E-mail:

WhatsApp:

Address:

500 meters west of the highway intersection in Xinxing Industrial Park, Yuanshi County, Hebei Province